An AC drive, also known as a variable frequency drive (VFD), uses a filter, an electrical component or device, to reduce or remove radio frequency interference (RFI) and/or electromagnetic interference (EMI) that the drive generates. The purpose of these filters is to lessen any electrical noise that the drive may produce, which might disrupt communication networks or interfere with nearby electronic equipment.

Allen Bradley AC drives convert the input AC power into an output with a changeable frequency and voltage so that an AC motor's speed and torque may be adjusted. During this conversion process, the electrical system may be exposed to high-frequency components and harmonics from the drive's switching operations. Interference may result from these high-frequency parts’ abilities to connect to other electrical parts and release electromagnetic emissions.

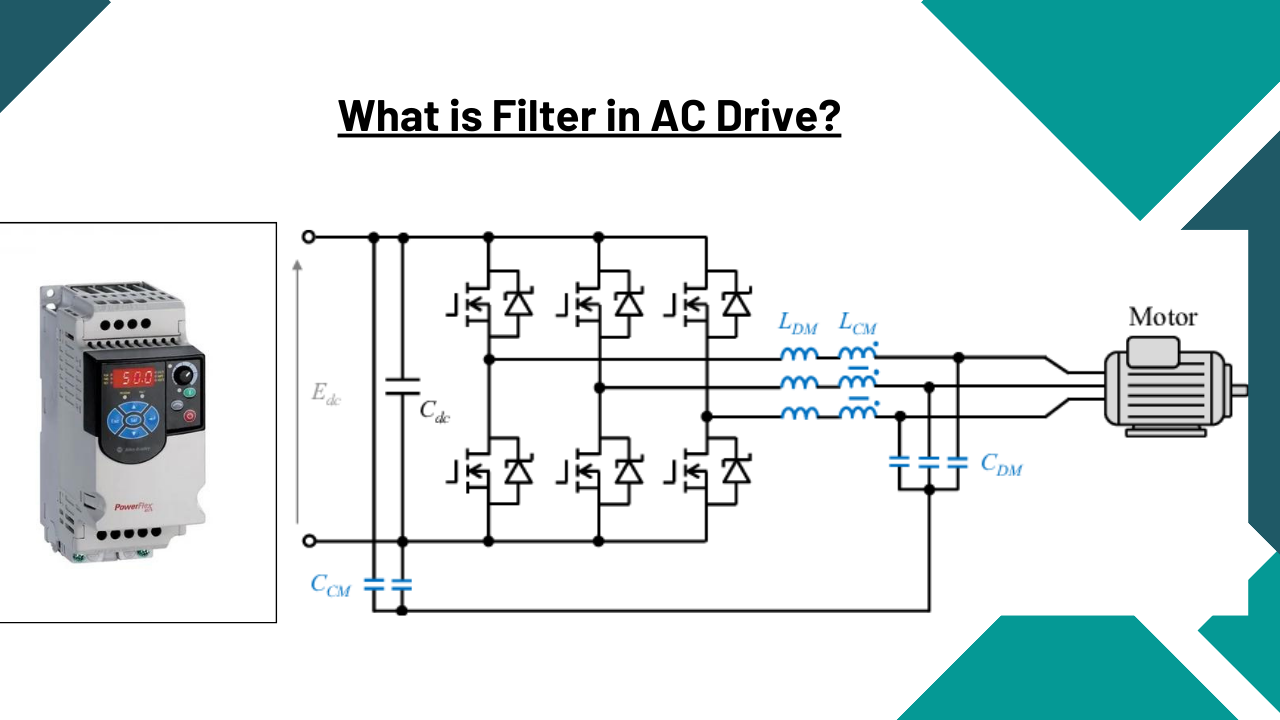

The input or output terminals of an AC drive are often linked to a filter. It is composed of passive components organised in certain ways to decrease or filter out unwanted electrical noise and harmonics, such as resistors, capacitors, and inductors.

The primary functions of a filter in an AC drive are:

1.EMI/RFI Suppression:

The filter helps lessen the electromagnetic and radio frequency interference that the Rockwell Automation AC drive generates. This suppression prevents the noise from the drive from damaging nearby electrical devices and communication networks.

- Electromagnetic Interference (EMI): An electronic system or equipment that is unable to function as intended is said to be experiencing electromagnetic interference, or EMI. Numerous sources might cause it, such as power lines, radio transmissions, electrical equipment running nearby, switching activities in electronic circuits, and more. Manifestations of electromagnetic interference (EMI) include electrical noise, voltage spikes, and electromagnetic radiation.

- Radio Frequency Interference (RFI): Interference caused by radio frequency waves is known as radio frequency interference, or RFI. These impulses might originate from radio transmitters, other electrical devices, or wireless devices. By producing unwanted signals, interfering with communication networks, or compromising the operation of delicate components, RFI can negatively impact electronic equipment.

2. Compliance with Regulatory Standards:

Filters are integrated onto AC drives in order to comply with electromagnetic compatibility (EMC) standards and laws. These rules outline the maximum levels of electromagnetic emissions that are allowed from electronic devices in order to minimise equipment interference.

- EMI/RFI Testing: Meeting EMC requirements frequently necessitates EMI/RFI testing of electronic systems and devices. This requires creating specific electromagnetic environments for the equipment, measuring the conducted and emitted emissions, and assessing the device's resilience to external electromagnetic disturbances. Usually, testing is carried out using specific equipment and methods at licenced labs.

- Certification and Markings: Successful adherence to EMC standards leads to certification or approval, which is usually granted by regulatory agencies or recognised certifying bodies. This certification may be mandatory or optional, depending on the application and market conditions. Electronic systems and gadgets can show the appropriate labels or markings, such as the CE mark in the EU or the FCC mark in the US, once they have been certified.

- Design Considerations: When designing for EMC compliance, there are several considerations to make across a product's whole lifespan. A few examples include the selection of suitable materials, suitable manufacturing techniques, careful PCB layout, component placement, and the usage of EMI filters and components.

Check :-Allen Bradley PowerFlex 4M AC drives

3.Protection of Electrical Equipment:

By reducing electrical noise and harmonics, filters assist protect other electrical equipment linked to the same power source from potential injury or malfunction caused by interference.

- Overvoltage Protection: Lightning strikes and other overvoltage events can cause harm to electrical equipment. By using surge arrestors or surge protection devices (SPDs), damage can be minimised by guiding excessive power away from sensitive equipment. These devices are frequently installed at the main electrical service entrance or placed on specific equipment to provide a conduit for the excess energy to discharge correctly.

- Overcurrent Protection: Overcurrents, such as excessive currents or short circuits, can endanger electrical equipment. Protection relays, circuit breakers, and fuses are used to identify and stop excessive currents and safeguard the associated wire and equipment. Appropriately sized and coordinated protective devices guarantee the dependable functioning of electrical systems.

- Grounding and Bonding: It is crucial to follow the right grounding and bonding methods in order to preserve electrical equipment. Grounding lowers the risk of electric shock by providing a low-impedance pathway for fault currents. By fostering electrical continuity between conductive parts, bonding reduces the likelihood of voltage fluctuations that might damage equipment or compromise signal integrity.

- Thermal Protection: In many electrical equipment, overheating can lead to reduced performance, early failure, or even fire hazards. Thermal protection devices such as thermal fuses, thermal overload relays, or temperature sensors are used to monitor and control the temperature of equipment. These gadgets have the ability to activate alarms or stop the machinery when temperatures rise over acceptable limits.

- Environmental Protection: Environmental factors such as dust, moisture, humidity, and corrosive substances can damage electrical equipment. Enclosures, cabinets, or protective coverings shield equipment from these elements, ensuring its reliability and prolonging its life. Furthermore, efficient ventilation and cooling systems help to disperse the heat generated by machinery, minimising thermal damage.

Asteam Techno Solutions Pvt ltd has

technical expert team with almost more than 10 years of experience in

industrial automation field who can assist you as well as suggest you best

possible solutions as per your need.

Comments