Unleashing Creativity: Custom Designs with CNC Milling

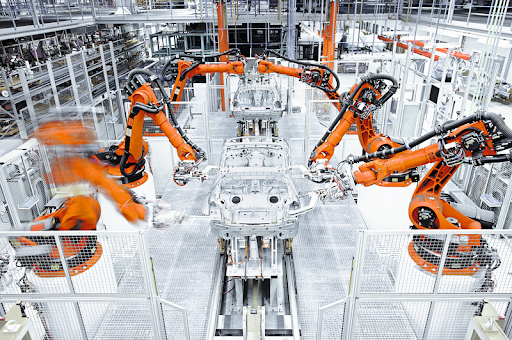

CNC milling, short for Computer Numerical Control Milling, has revolutionized the manufacturing industry, offering unprecedented precision and efficiency in creating custom designs. This article delves into the intersection of creativity and CNC milling, exploring how this technology enables the realization of unique and innovative designs.

Introduction to CNC Milling

CNC milling is a subtractive manufacturing process where a computer-controlled machine removes material from a workpiece to create a custom-designed product. Unlike traditional manual milling, CNC milling automates the process, allowing for higher accuracy and repeatability.

Understanding Creativity in Design

Creativity in design involves the ability to think outside the box, pushing boundaries, and exploring new possibilities. It's about translating ideas into tangible products that resonate with users on an emotional level.

Benefits of CNC Milling in Custom Designs

Precision and Accuracy

CNC milling offers unparalleled precision, ensuring that every detail of the design is faithfully reproduced. This precision allows for intricate and complex designs that would be challenging to achieve using traditional methods.

Versatility in Materials

One of the key advantages of CNC milling is its versatility in working with a wide range of materials, including metals, plastics, and wood. This flexibility opens up endless possibilities for creative experimentation and innovation.

Complex Designs Made Simple

With CNC milling, even the most intricate designs can be realized with ease. Complex shapes, curves, and patterns that would be difficult or impossible to achieve manually can be effortlessly produced using computer-controlled machines.

Exploring Creative Possibilities

Personalized Products

CNC milling enables the creation of personalized products tailored to individual preferences and specifications. Whether it's custom jewelry, furniture, or electronic devices, CNC technology allows for mass customization at a fraction of the cost of traditional methods.

Intricate Patterns and Textures

From intricate lace-like patterns to textured surfaces reminiscent of natural materials, CNC milling offers endless possibilities for adding visual interest and tactile appeal to designs. These intricate details can elevate the aesthetic value of products, making them stand out in a crowded market.

Customized Prototypes

In product development, prototyping is a crucial stage for testing and refining designs before mass production. CNC milling allows for the rapid prototyping of custom designs, enabling designers to quickly iterate and fine-tune their concepts based on real-world feedback.

Overcoming Challenges in CNC Milling

Design Limitations

While CNC milling offers significant creative freedom, there are still certain design limitations to consider. Factors such as tool size, material properties, and machine capabilities may impose constraints on the complexity and scale of designs.

Material Constraints

The choice of material plays a critical role in the success of a CNC milling project. Different materials have unique properties and machining characteristics that must be taken into account during the design process to ensure optimal results.

Cost Considerations

CNC milling can be cost-effective for mass production but may pose challenges for small-scale or one-off projects. Factors such as machine setup time, material waste, and labor costs can significantly impact the overall cost of production.

Tips for Unleashing Creativity

Design Iteration

Creativity thrives on iteration and refinement. Experiment with different design iterations, exploring alternative solutions, and pushing the boundaries of what's possible with CNC milling.

Collaboration with CNC Experts

I will collaborate with CNC experts and technicians to leverage their expertise and experience in optimizing designs for manufacturing. Their insights can help streamline the production process and avoid potential pitfalls.

Incorporating Feedback

Seek feedback from end-users and stakeholders throughout the design process. Their input can provide valuable insights into improving usability, functionality, and aesthetics, ultimately resulting in a more successful product.

Case Studies: Innovative CNC Designs

Custom Furniture Design

A furniture designer utilizes CNC milling to create bespoke pieces with intricate patterns and sculptural forms, pushing the boundaries of traditional woodworking techniques.

Architectural Ornamentation

An architect incorporates CNC-milled elements into building facades, creating visually striking designs that blur the line between art and architecture.

Future Trends in CNC Milling

Automation and AI Integration

Advancements in automation and artificial intelligence are poised to revolutionize CNC milling, making it faster, more efficient, and accessible to a wider audience.

Sustainability and Eco-Friendly Practices

As environmental concerns become increasingly important, there is growing interest in sustainable materials and eco-friendly manufacturing processes within the CNC milling industry.

Accessibility and Affordability

Technological advancements and economies of scale are driving down the cost of CNC milling, making it more accessible to small businesses, entrepreneurs, and hobbyists.

Conclusion

In conclusion, CNC milling offers unparalleled opportunities for unleashing creativity in design. By harnessing the precision, versatility, and efficiency of this technology, designers can bring their wildest ideas to life, pushing the boundaries of what's possible in custom manufacturing.

Comments