Modern industrial environments cannot compromise dependability or efficiency. Perfect equipment is those that can constantly provide great performance and be flexible enough for several uses. One of the best examples of such tools, often known for their adaptability and longevity are liquid ring vacuum pumps. Many industries, including chemical processing, electricity generation, and pharmaceuticals, depend on these pumps absolutely. But what precisely distinguishes these pumps, and how may they be applied to improve your manufacturing processes?

What Are Liquid Ring Vacuum Pumps?

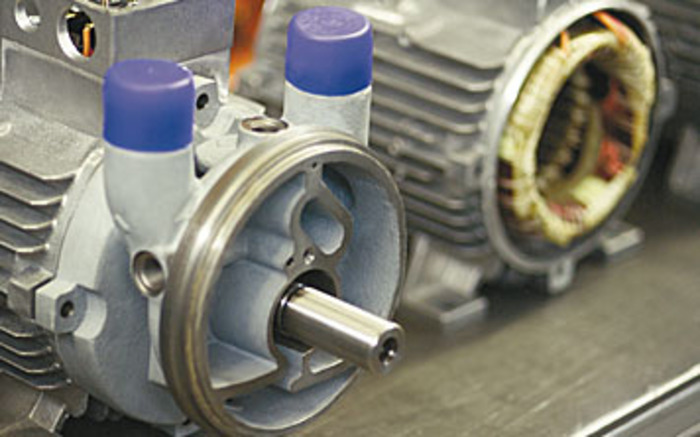

Typically water, liquid ring vacuum pumps are mechanical devices using a revolving impeller inside a casing filled with liquid to produce a vacuum. The impeller's rotating movement makes a liquid ring inside the casing that generates a sequence of enclosed chambers. These chambers compress gas or vapor, trap it, then release it creating a vacuum.

With few moving components and simple construction, this produces a dependable and strong pump. The liquid ring absorbs heat and serves as a seal, therefore preventing the pump from overheating and guaranteeing flawless performance even under high demand. This makes liquid ring vacuum pumps especially fit for uses where gases might be corrosive, moist, or unclean.

Liquid Ring Vacuum Pools' Benefits

Reliability and Durability

Low maintenance demands and long service life of liquid ring vacuum pumps are well-known. By means of a cushioning action, the liquid ring lowers wear and strain on the impeller and casing, therefore extending the operating life of the pump. In sectors where equipment breakdown could cause major losses, this dependability is absolutely vital.

Adaptability

Highly flexible, these pumps can manage a wide range of gases and vapours—including those combined with liquids. For sectors like chemical processing, where the capacity to control many kinds of chemicals is crucial, they are therefore perfect. Their versatility also shows in uses ranging from vacuum filtration to degassing.

Effective Function

Liquid ring vacuum pumps run effectively over a range of situations. Even under changing loads or contaminated gasses, they keep a constant vacuum level. Their silence and low vibration help to further appeal in delicate industrial areas.

Uses for Liquid Ring Vacuum Pumps

Chemical Handling

Liquid ring vacuum pumps are absolutely indispensable in chemical processes. Distillation, drying, and filtering are only a few of the several stages of manufacturing they are applied in. In this sector, they are a recommended alternative since one can manage corrosive gases and vapors without sacrificing performance. Furthermore frequently coupled with other systems, such the shell and tube heat exchanger, these pumps help to maximize efficiency and streamline operations.

Power Creation

For important jobs such water deaeration and condenser air extraction, power plants depend on liquid ring vacuum pumps. By guaranteeing efficient removal of air and other non-condensible gases, these pumps serve to sustain the efficiency of the power generating process. Their strong construction lets them run consistently in the demanding surroundings of power producing plants.

Pharmaceuticals

In its operations, the pharmaceutical sector expects great purity and precision. For uses including vacuum drying, freeze-drying, and solvent recovery—where a consistent vacuum source is needed—liquid ring vacuum pumps satisfy these needs. Making premium pharmaceutical products depends much on their capacity to manage sensitive components free of contamination.

Food and Beverage

Liquid ring vacuum pumps find usage in the food and beverage sector for operations including degassing, juice concentration, and vacuum packing as well as Their capacity to control liquids and gases guarantees effective operation of procedures, thereby maintaining the quality and safety of the produced goods.

Integrating Liquid Ring Vacuum Pumps with Shell & Tube Heat Exchangers

Liquid ring vacuum pump interaction with other equipment, including the shell and tube heat exchanger, is absolutely important for best performance. Designed to transfer heat between two fluids, one running through the tubes and the other encircling them within the shell, a shell and tube heat exchanger Maintaining the liquid's temperature utilized in the vacuum pump depends on this equipment, which also helps to prevent overheating of the liquid.

The shell & tube heat exchanger guarantees that the liquid in the pump stays at an ideal temperature in systems involving high temperatures, including those in chemical manufacture or power generation. This increases the pump's efficiency as well as extends its lifetime, therefore lowering maintenance costs and downtime.

Maintenance Tips for Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps must be routinely maintained to guarantee their lifetime and performance. Here are some important pointers on upkeep:

Monitor the Liquid Level

Make that the advised range of the liquid ring level is kept within. While too much liquid might cause operational problems, inadequate liquid can result in lower efficiency and possible pump failure.

Check for Contaminants

Check the liquid often for anything that can compromise the pump's operation. To preserve best operation, contaminants should be eliminated and, if needed, the liquid should be changed.

Examining the Impeller

Look at the impeller often for wear or damage. Any problems should be fixed quickly to prevent any harm and guarantee the pump keeps running effectively.

Guarantee correct integration with heat exchangers

Should your pump be coupled with a shell and tube heat exchanger, routinely inspect the exchanger for leaks or obstructions. Maintaining the performance of the pump depends on a proper operation of the heat exchanger.

Conclusion

Essential instruments in many different fields, liquid ring vacuum pumps provide dependability, adaptability, and effective running performance. Industries may maximize their processes and reach long-term operational excellence by knowing their uses and combining them with systems like the shell & tube heat exchanger.

Ensuring that these pumps keep running at their best mostly depends on regular maintenance and close observation. Liquid ring vacuum pumps will only become more crucial as businesses change and needs rise in order to keep dependable and effective operations.

Comments