Understanding Shell & Tube Heat Exchangers

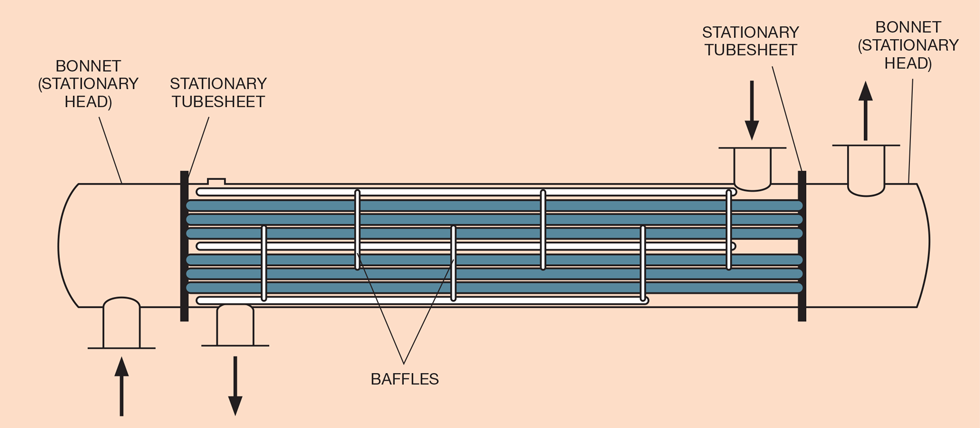

A shell & tube warm temperature exchanger is a shape of heat exchanger that includes a series of tubes, one set sporting the present day fluid and the alternative wearing the cold fluid. The warmth is transferred via the partitions of the tubes, considering inexperienced thermal change. This format is considerably applied in industries collectively with oil and gasoline, energy gera, chemical processing, and HVAC systems because of its capability to address immoderate pressures and temperatures.Key Features of Shell & Tube Heat Exchangers

- Robust Design: The creation of shell & tube heat exchangers lets in them to stand as much as intense conditions, making them suitable for heavy-obligation programs.

- Versatility: These warmth exchangers can be designed to accommodate diverse fluids, such as gases and drinks, making them exceptionally versatile for one of a kind tactics.

- High Heat Transfer Efficiency: The layout allows powerful warmness transfer, leading to progressed thermal overall performance and reduced strength consumption.

The Advantages of Investing in Shell & Tube Heat Exchangers

- Enhanced Energy Efficiency

One of the primary reasons to do not forget a shell & tube warmness exchanger is its ability to enhance power efficiency. By correctly shifting warmness among fluids, those exchangers minimize the energy required to heat or cool a substance. This no longer handiest reduces operational costs however additionally contributes to sustainability efforts by means of reducing overall strength intake. - Improved Process Control

Precision in temperature control is critical for plenty industrial techniques. Shell & tube warmth exchangers provide great temperature control, permitting operators to maintain top-quality conditions for his or her operations. This capability can result in higher product high-quality and reduced waste, at once impacting the lowest line. - Space Efficiency

The compact layout of shell & tube heat exchangers allows for more green use of space inside a facility. Unlike other heat exchanger types that can require more vast installations, the shell & tube layout can healthy into tighter spaces, enabling better facility layout and probably reducing universal construction charges. - Durability and Longevity

Investing in a shell & tube heat exchanger can result in long-term benefits because of its robust construction. These heat exchangers are designed to remaining, withstanding harsh operational environments, which reduces the want for common replacements and protection. This durability interprets into decrease lifetime costs, making them a smart funding for groups. - Adaptability to Changing Needs

As industries evolve, so do their operational desires. Shell & tube heat exchangers may be custom designed to fulfill specific requirements, permitting corporations to evolve to adjustments in production or regulatory requirements. This adaptability guarantees that the investment remains precious whilst the marketplace panorama shifts.

Comparing Shell & Tube Heat Exchangers with Air Cooled Heat Exchangers

While shell & tube warmness exchangers provide severa advantages, it's miles critical to apprehend how they examine with air cooled heat exchangers, any other popular choice in warmness switch programs.

- Operating Principle

Air cooled heat exchangers utilize ambient air to cast off warmth from the fluid, relying on fanatics or natural convection. In contrast, shell & tube warmness exchangers switch heat through a chain of tubes, taking into consideration a more controlled and efficient heat trade technique, especially in programs wherein water or different coolants are available. - Efficiency in Different Conditions

Shell & tube heat exchangers are frequently more green in high-temperature and excessive-pressure programs. They are better proper for industries that require rigorous thermal control, which include petrochemicals. On the opposite hand, air cooled warmth exchangers can be more effective in environments with restricted water deliver, as they do no longer require liquid coolants. - Maintenance Considerations

Maintenance is crucial for both kinds of heat exchangers. While shell & tube warmness exchangers might also require periodic cleansing and inspections, their robust design can motive a whole lot much less frequent issuer interruptions in assessment to air cooled warm temperature exchangers, which can also require greater normal safety due to dust and debris accumulation.

Best Practices for Implementing Shell & Tube Heat Exchangers

- Conduct a Thorough Needs Assessment

Before making an investment in a shell & tube warmness exchanger, conduct a complete evaluation of your operational necessities. Consider factors which includes fluid sorts, temperature levels, stress degrees, and area constraints to make certain you pick out the proper version for your desires. - Collaborate with Engineering Experts

Engage with engineering professionals who focus on warmness exchanger design and installation. Their understanding will let you navigate the complexities of choosing and implementing a shell & tube heat exchanger, making sure best performance. - Invest in Quality Components

Quality matters in terms of warmth exchangers. Select a shell & tube warmth exchanger made out of high-grade materials which can withstand the specific situations of your operation. This investment can pay off in terms of toughness and performance. - Regular Maintenance and Inspections

To ensure the sturdiness and efficiency of your shell & tube warmness exchanger, establish a normal renovation and inspection time table. This proactive method will assist become aware of capacity troubles before they increase, minimizing downtime and repair prices.

Conclusion

In end, in case you are trying to improve your operations, investing in modern-day shell & tube warmness exchangers can be a strategic flow. Their energy performance, sturdiness, and flexibility to various industrial needs make them an notable choice for enhancing performance across numerous packages. By expertise the advantages they provide and the way they compare with air cooled warmness exchangers, you can make an knowledgeable decision that aligns with your operational dreams. Embracing this generation now not only positions your commercial enterprise for fulfillment however also contributes to a greater sustainable future in commercial practices.

Comments