Heat exchangers play a essential characteristic in preserving the general overall performance of business business organisation systems thru transferring warm temperature amongst one-of-a-kind fluids or gases. Two of the most usually used forms of warmth exchangers are plate fin warmth exchangers and air cooled heat exchangers. While every serve the equal essential cause, they've got specific designs and safety necessities. But how precisely do they range in terms of maintenance dreams? This blog explores the critical aspect elements that distinguish the protection of plate fin warmth exchangers and air cooled warm temperature exchangers, and the manner those variations have an impact on their performance, durability, and operational ordinary overall performance.

What Is a Plate Fin Heat Exchanger?

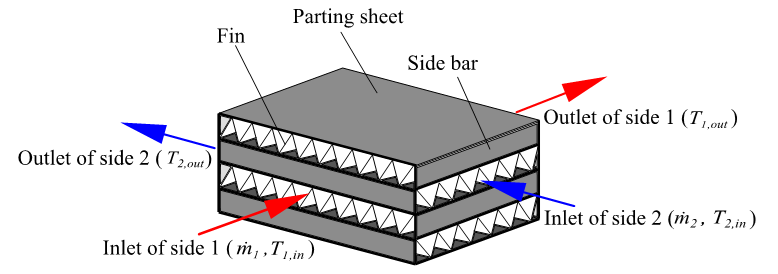

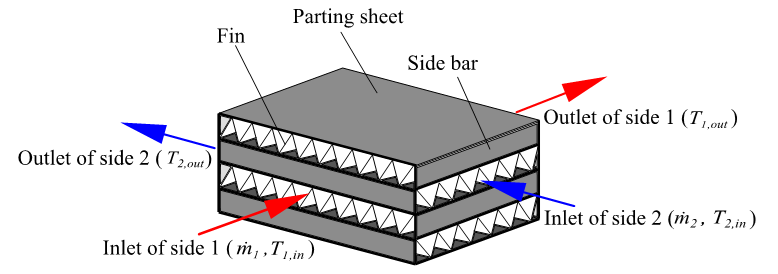

A plate fin warmth exchanger is a form of heat exchanger designed with a chain of flat plates stacked together, with fins placed amongst them to boom the ground area for heat switch. This format is usually applied in programs in which vicinity is confined and immoderate warmth switch general overall performance is wanted. The warm temperature exchanger works with the useful resource of allowing fluids or gases to go with the drift through the plates, while warm temperature is transferred some of the fluids thru the fins.

How Does the Design of Plate Fin Heat Exchangers Affect Maintenance?

The difficult layout of plate fin heat exchanger may want to make protection a chunk greater difficult. These warmth exchangers have a compact shape, often making get entry to to internal components which embody plates and fins greater hard. However, their format is proper for managing immoderate pressure and ensuring green warmth switch.

Maintenance for plate fin warmth exchangers usually consists of analyzing the plates for symptoms and signs and symptoms and signs and symptoms of corrosion, placed on, or fouling. Over time, debris, sediment, and contaminants can constructing up among the plates, affecting warmth switch overall performance. Regular cleaning and inspection are vital to make certain that the warmth exchanger continues to carry out optimally.

What Is an Air Cooled Heat Exchanger?

On the possibility hand, air cooled warm temperature exchangers rent ambient air as a cooling medium. These heat exchangers characteristic a chain of finned tubes that permit air to pass via, dissipating the heat from the fluid inner. This form of heat exchanger is usually utilized in environments wherein water belongings are scarce or wherein a liquid cooling tool isn't feasible.

How Does the Design of Air Cooled Heat Exchangers Impact Maintenance?

Unlike plate fin warmth exchangers, air cooled warmth exchangers depend upon air for warmth dissipation, due to this they may be exposed to pretty some environmental factors, which consist of dirt, dirt, and particles. These elements can clog the fins and function an effect on the general performance of the exchanger, maximum vital to a reduction in warmness transfer ordinary performance. As a cease prevent cease result, regular cleansing and protection of the out of doors components, which incorporates the fins and the air intakes, are essential for retaining ordinary performance.

Air cooled heat exchangers are typically lots less tough to preserve than plate fin warm temperature exchangers due to their greater on hand layout. The out of doors components, collectively with the fins and tubes, are fairly easy to clean, and the renovation manner is usually confined to periodic cleansing and inspection for corrosion or physical damage.

How Does Fouling Affect Maintenance in Both Types of Heat Exchangers?

Fouling refers to the buildup of undesirable substances, in conjunction with scale, dust, and biological depend, on the warmth exchanger surfaces. This can substantially lessen the warm temperature switch overall performance of the exchanger. Both plate fin warm temperature exchangers and air cooled warmth exchangers are prone to fouling, however the effect and upkeep requirements can variety.

Plate Fin Heat Exchanger Fouling

Fouling in plate fin warmness exchangers can be particularly hard because of the small gaps between the plates and fins. When fouling takes area, it could be greater tough to clean the surfaces successfully. To mitigate fouling, regular cleansing and the usage of filtration systems can help lessen the buildup of debris within the exchanger. Additionally, chemical cleaning also can occasionally be required to eliminate cussed fouling deposits from the plates.

Air Cooled Heat Exchanger FoulingIn air cooled heat exchangers, fouling usually happens on the external fins and tubes. The buildup of dirt and debris can clog the fins, decreasing airflow and impacting warmth switch. In the ones structures, ordinary cleaning of the fins is essential to make certain proper operation. High-stress air or water jets can be used to smooth the fins, or specialised brushes may be employed to take away amassed dust. Depending at the surroundings in which the warmth exchanger operates, cleansing frequency might also need to be better, particularly in dusty or polluted regions.

What Are the Common Maintenance Tasks for Plate Fin Heat Exchangers?

To ensure maximum beneficial standard performance, ordinary safety of plate fin warm temperature exchangers consists of the following obligations:

1. Cleaning the Plates and Fins

As fouling can notably lessen the warm temperature transfer overall performance, cleansing the plates and fins often is vital. This way can also comprise chemical cleansing, specially in cases wherein stubborn deposits have original. It's critical to make certain that the cleaning approach does now not damage the sensitive shape of the plates.

2. Inspecting for Corrosion or Damage

Corrosion can weaken the plates and fins, predominant to reduced overall performance or leaks. Regular visual inspections and non-damaging finding out (which includes ultrasonic or dye penetrant attempting out) are important for detecting early signs and symptoms and signs of corrosion or physical damage.

3. Replacing Gaskets and Seals

The seals a few of the plates want to be often checked and changed if worn out to hold the integrity of the heat exchanger and avoid leaks.

4. Checking for Leaks

Leakage can lessen the performance of plate fin warmth exchangers and want to be at once addressed. Regular stress trying out can help stumble on any problems.

What Are the Common Maintenance Tasks for Air Cooled Heat Exchangers?

For air cooled warmth exchangers, protection obligations regularly recognition on outdoor additives and airflow performance:

1. Cleaning the Fins

The fins on air cooled warm temperature exchangers can collect dirt, dust, and debris. Regular cleansing the usage of air jets or brushes is crucial to make certain that the airflow isn't always obstructed.

2. Inspecting for Physical Damage

Regular inspection of the fins and tubes for bodily harm, which incorporates dents or cracks, is critical to prevent air leaks or performance losses.

3. Checking for Corrosion

Corrosion could have an effect on the general overall performance of the warm temperature exchanger, specially in humid or salty environments. Periodic tests for corrosion and the software program of anti-corrosion remedies can assist amplify the existence of the warmth exchanger.

4. Monitoring Fan Operation

In air cooled warmth exchangers, the fans play a key role in preserving airflow. Checking for any motor or fan blade malfunctions and ensuring proper lubrication is a part of the protection recurring.

How Do Maintenance Costs Compare Between Plate Fin and Air Cooled Heat Exchangers?

While each plate fin warmth exchangers and air cooled warmth exchangers require ongoing safety, the expenses can range. The greater complicated format of plate fin warm temperature exchangers might also result in better upkeep costs because of the trouble of cleansing and the capability want for chemical remedies. In evaluation, air cooled warmth exchangers commonly have lower safety prices, as their outside additives are more handy and plenty much less complicated to keep.

However, the overall charge of safety can also rely upon factors alongside facet the on foot surroundings, the complexity of the machine, and the extent of fouling or corrosion present. Proper protection can assist reduce unexpected renovation and make certain that every types of warm temperature exchangers hold to feature effectively.

Conclusion

In summary, each plate fin heat exchangers and air cooled heat exchangers require everyday maintenance to perform efficiently. However, their layout and operational versions reason exquisite protection goals. Plate fin warm temperature exchangers require greater detailed safety due to their compact layout and internal components, at the equal time as air cooled warm temperature exchangers are easier to maintain with a focus on cleansing outside additives and ensuring proper airflow. Understanding the perfect protection necessities of every tool is essential for prolonging their lifespan and preserving excessive universal overall performance in industrial programs.

Comments